Depending on the type of fermentation the brewing process is different for each beer. Basically the beer recipe.

Expect an intense course where you will get an understanding of the brewing process including its many terms such as barley malting hops water brewhouse technology brewers yeast microorganisms fermentation maturation stabilisation filtration packaging technology taste testing and beer styles.

Basic beer brewing process. Using an auto-siphon move the beer from the boiling pot into carboys. Leave lots of head room in your carboys because the beer will bubble up significantly during the fermentation process. Cap the carboys with airlocks and store somewhere dark and relatively cool 67F.

Expect an intense course where you will get an understanding of the brewing process including its many terms such as barley malting hops water brewhouse technology brewers yeast microorganisms fermentation maturation stabilisation filtration packaging technology taste testing and beer styles. Fill your 5-gallon brew kettle with 25 gallons of water. As you heat your water steep your grains for 20 minutes or until your water reaches 170 degrees.

When you remove your grains let the water drip out of the grain bag and into the kettle. Learn the Step-by-Step Process Of Brewing Beer Explained in Animated GIFs Step 1. Beginning In the brew house different types of malt are crushed together to break up the.

The grist is then transferred into. The basic ingredients for each beer are. Water barley malt hops and yeast.

Depending on the type of fermentation the brewing process is different for each beer. At Brewery Omer Vander Ghinste beers are brewed from top bottom spontaneous and mixed fermentation. Discover the different steps in the process.

I know this probably sounds pretty basic but to become craft brewers we need to understand our craft in its most basic form. Beer is a living and breathing piece of art more on this when we cover fermentation in section 5. Before we can create our own biological masterpiece however we have to understand beers basic DNA.

Theres obviously far more to beer than this and well get to all of those specifics in future posts. For now though if someone asks you what beer is youll have a pretty good and well-educated answer. In the next lesson well look at the basics of brewing to.

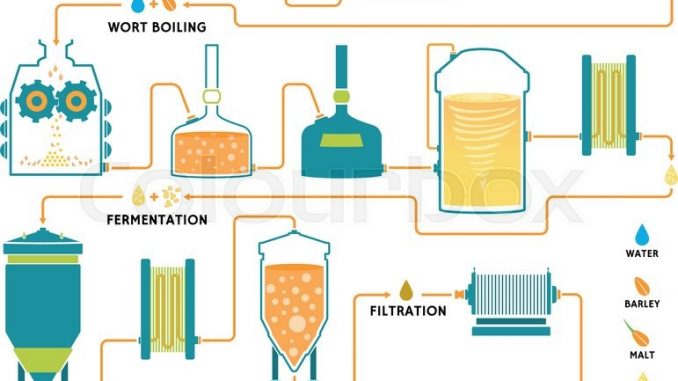

The brewing process is made up of ten production steps from the fresh barley to the finished beer we would like to present these steps in more detail. The brewing process begins with malting milling mashing and lautering. Nine steps are involved during brewing process.

Wort separation and cooling. Beer making process Source. The Basics of Brewing Beer Beer is a fantastic beverage available in a wide selection of flavors and styles but all beers share four common ingredients.

Malt Yeast Hops and Water. Malt or malt extract provide the sugars necessary for the fermentation process. More malt equals more sugar.

This in turn equals more alcoholic strength. To begin the fermentation process you transfer cooled wort to a fermenting vessel and add the yeast. During this process the yeast converts the sugar in the wort to alcohol and CO2.

Important flavour compounds are also being created at this stage. In the context of brewing metabolic process driven by yeast to convert wort into beer Hops. Bitter flowers of the hop plant used to flavor and stabilize beer Grain bill.

Proportion of grains in a beer ie mash ingredients. Basically the beer recipe. The Actual Brewing Process This is where all the fun begins.

To start off heat water in a kettle or a suitable container along with the grain and steep it for about 20 minutes. Once everything has been boiled up empty the water content with the help of a grain bag. However if you are looking to improve your brewing process experiment with glass fermenters.

Glass fermenters are impermeable to oxygen less prone to scratching and are much easier to clean than plastic models. Switching to glass could increase the sanitation of your brewing process which will in turn improve the taste of your beer.